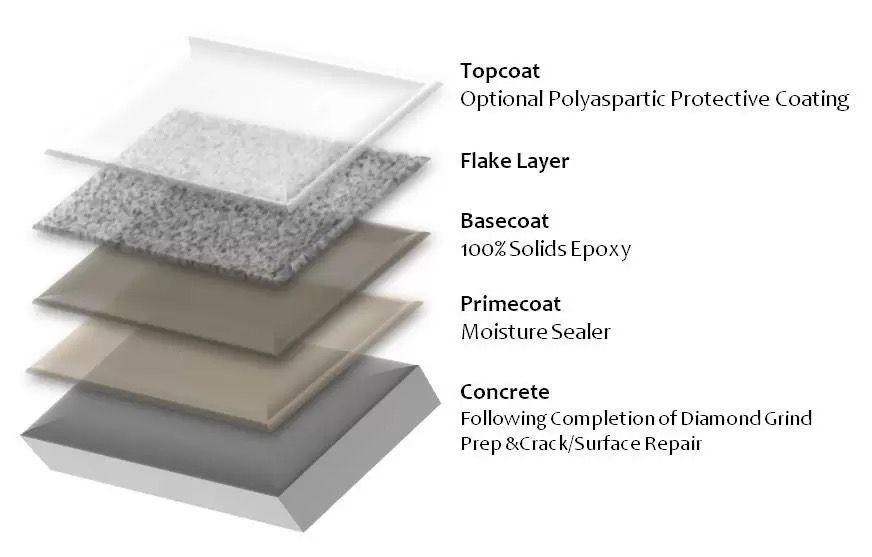

Concrete Coatings in North Florida: Why You Need A Moisture Barrier When Having Epoxy Concrete Floor Coatings Installed

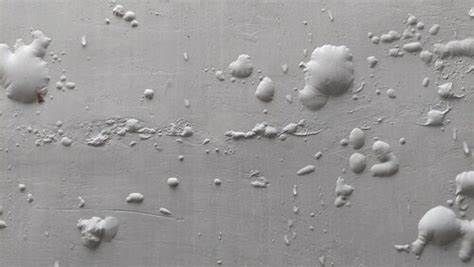

A moisture barrier is a crucial step when applying epoxy coatings in hot and humid Northeast Florida, especially over concrete substrates. Its main purpose is to prevent moisture vapor transmission (MVT) from the concrete slab, which can cause delamination of the epoxy coating, bubbling or blistering, poor adhesion and coating failure.

Concrete is porous and often contains moisture, especially:

If not properly addressed, this moisture can migrate up through the slab and disrupt the epoxy coating.

Why Moisture Barriers Are Needed

Concrete is porous and often contains moisture, especially:

- In new slabs (curing can take months)

- In areas with high ground water

- On-grade or below-grade slabs without a vapor barrier underneath

If not properly addressed, this moisture can migrate up through the slab and disrupt the epoxy coating.